- This topic is empty.

-

AuthorPosts

-

2025-01-09 at 6:00 pm #62982

https://www.magicmag-tech.com/The-Technical-Advantages-of-Fixed-Speed-Magnetic-Couplers.html

Efficient Power Transmission

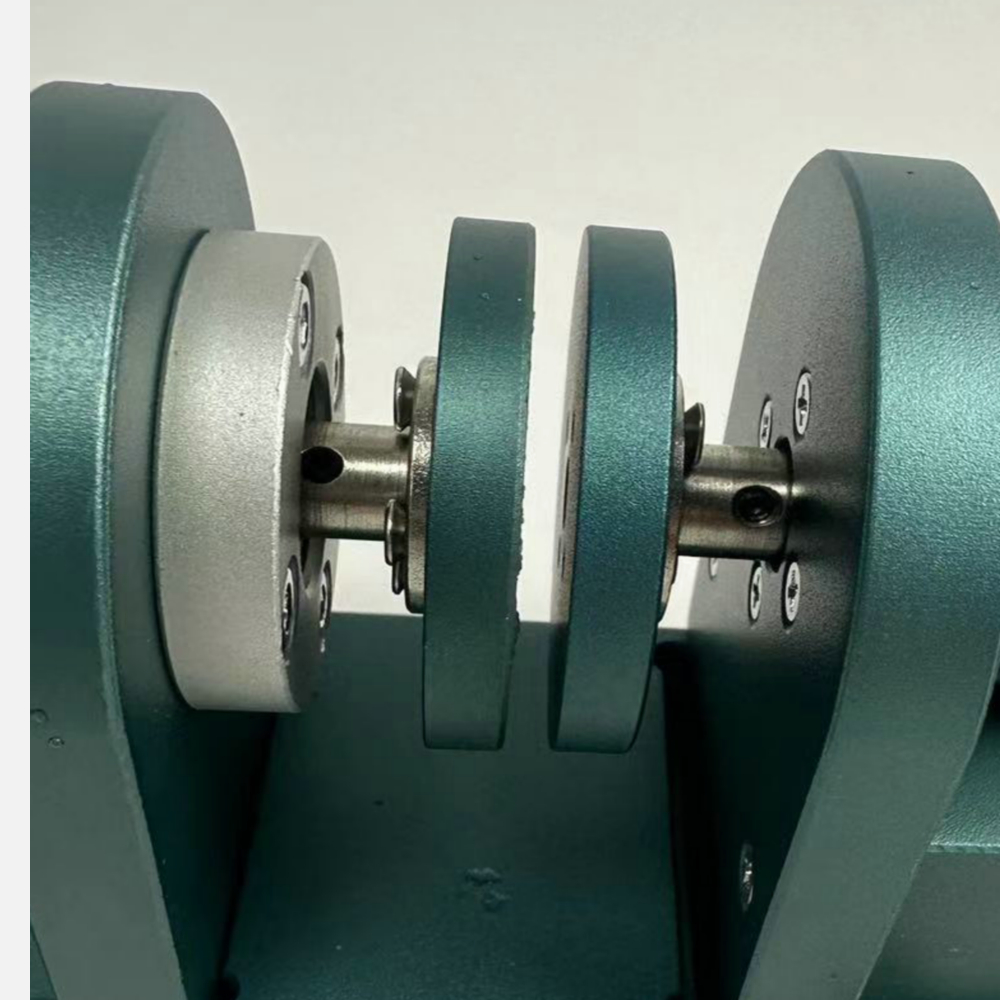

SHANGHAI GAOLV E&M TECHNOLOGY CO.,LTD. is a professional fixed speed magnetic coupler supplier. Our fixed speed couplings series include basic model principle type magnetic coupling, disc type magnetic coupling and cylinder magnetic coupling.

One of the most notable advantages of fixed speed magnetic couplers is their exceptional efficiency in power transmission. Unlike traditional mechanical couplings, which rely on physical contact between components to transfer torque, magnetic couplers utilize magnetic fields to achieve the same goal. This magnetic interaction allows for a seamless transfer of energy with minimal losses.

The efficiency of fixed speed magnetic couplers can be attributed to several factors. Firstly, the absence of friction between the driving and driven components significantly reduces energy dissipation. Friction, which is inherent in mechanical couplings, generates heat and consumes additional energy, thereby lowering the overall efficiency of the system. In contrast, magnetic couplers maintain a high level of efficiency by minimizing these frictional losses.

Moreover, the magnetic fields used in these couplers are carefully designed and optimized to ensure maximum power transfer. The arrangement of permanent magnets and the magnetic circuit are engineered to create a strong and stable magnetic field that effectively transfers torque from the input shaft to the output shaft. This precise control of the magnetic field results in a high power transmission efficiency, often exceeding 95% in many applications.

The high efficiency of fixed speed magnetic couplers translates into tangible benefits for industrial operations. For instance, it leads to reduced energy consumption, which not only lowers operational costs but also contributes to a smaller carbon footprint. Additionally, the efficient power transmission enhances the overall performance of the machinery, ensuring that the equipment operates at its optimal capacity.

Contactless Operation

Another significant advantage of fixed speed magnetic couplers is their contactless operation. The magnetic coupling mechanism eliminates the need for direct physical contact between the driving and driven components. This feature has several important implications for the performance and maintenance of the system.

Firstly, the absence of contact means that there is no wear and tear on the coupling components. In traditional mechanical couplings, the continuous friction and contact between parts can lead to wear over time. This wear can result in reduced efficiency, increased maintenance requirements, and potential equipment failures. Magnetic couplers, on the other hand, do not experience this type of wear, as the torque is transmitted through the magnetic field rather than through direct contact.

The contactless nature of fixed speed magnetic couplers also reduces the need for lubrication. Mechanical couplings often require regular lubrication to minimize friction and wear, which can be a time-consuming and costly maintenance task. With magnetic couplers, the lack of contact eliminates the need for lubrication, simplifying maintenance procedures and reducing maintenance costs.

Furthermore, the contactless operation enhances the reliability and lifespan of the system. The absence of wear and the need for lubrication means that the coupling components are less prone to failure. This increased reliability ensures that the equipment can operate continuously without frequent interruptions due to coupling-related issues, leading to improved productivity and reduced downtime.

Overload Protection

Fixed speed magnetic couplers are equipped with a built-in overload protection mechanism, which is a crucial feature for safeguarding equipment and preventing damage. In the event of an overload condition, where the torque exceeds the rated capacity of the coupling, the magnetic field can be designed to automatically disengage or slip. This disengagement prevents excessive torque from being transmitted to the driven equipment, thereby protecting it from potential damage.

The overload protection capability of magnetic couplers is particularly beneficial in applications where sudden load changes or unexpected overloads can occur. For example, in industrial processes involving heavy machinery or equipment with variable loads, the risk of overloading is relatively high. In such cases, the magnetic coupling's ability to disconnect under overload conditions ensures that the equipment remains safe and operational.

Moreover, this protective feature allows for a more controlled and predictable operation of the machinery. Operators can have confidence that the coupling will not transmit excessive torque, reducing the risk of equipment failure and costly repairs. This peace of mind contributes to a more efficient and reliable industrial process.

https://www.magicmag-tech.com/The-Technical-Advantages-of-Fixed-Speed-Magnetic-Couplers.html

SHANGHAI GAOLV E&M Technology Co.,Ltd. -

AuthorPosts

- You must be logged in to reply to this topic.