- This topic is empty.

-

AuthorPosts

-

2024-11-20 at 11:45 am #62668

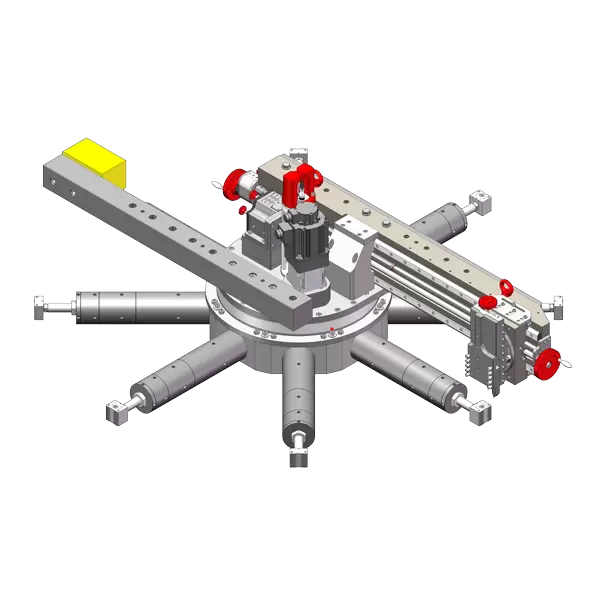

The flange facing machine is a commonly used mechanical equipment used to process the end face of the flange. However, due to long-term use and wear, the tool of the flange facing machine often has wear problems. This article will explore how to solve the problem of tool wear of the flange facing machine to improve the service life and work efficiency of the machine.

1. Understand the causes of tool wear

Before solving the problem of tool wear of the flange facing machine, we first need to understand the causes of tool wear. Tool wear mainly has the following reasons:

1.1 Selection of tool material

The selection of tool material directly affects the hardness and wear resistance of the tool. If the hardness of the selected tool material is not high enough or the wear resistance is not good enough, then the tool is prone to wear problems during long-term use.

1.2 Selection of processing technology

The selection of processing technology will also affect the wear of the tool. If the selected processing technology is unreasonable, such as too fast cutting speed, too high feed speed, etc., it will cause the tool to wear more severely.

1.3 Influence of the use environment

The influence of the use environment is also one of the important reasons for tool wear. For example, if there are a lot of dust, oil and other impurities in the use environment, these impurities will enter the cutting area of the tool, causing the tool to wear more severely.

2. Methods to solve tool wear problems

After understanding the causes of tool wear, we can take the following methods to solve the tool wear problem of flange end face machine:

2.1 Choose the right tool material

First, we need to choose the right tool material. The hardness and wear resistance of the tool material are important indicators of the tool. We can choose the right tool material according to the specific processing requirements. For example, for processing that requires high hardness and wear resistance, you can choose materials such as high-speed steel or cemented carbide.

2.2 Optimize the processing technology

Secondly, we can reduce tool wear by optimizing the processing technology. Reasonable selection of parameters such as cutting speed, feed speed and cutting depth can reduce the degree of tool wear. In addition, lubricants or coolants can be used to reduce cutting temperature and reduce tool wear.

2.3 Strengthen maintenance and cleaning

Regular maintenance and cleaning of flange end face machines is also one of the important methods to solve tool wear problems. Regularly replacing tools and cleaning tools and cutting areas can effectively reduce tool wear. In addition, equipment such as protective covers or filters can be installed to prevent dust and impurities from entering the cutting area.

2.4 Improve operating skills

Improving operating skills is also the key to solving tool wear problems. Operators need to be proficient in the use and operating procedures of flange facing machines, use tools correctly, and avoid unnecessary wear. In addition, training can be strengthened to improve the skill level of operators and reduce the possibility of operating errors and accidents.

Through the above methods, we can effectively solve the problem of tool wear of flange facing machines and improve the service life and work efficiency of the machine. Selecting suitable tool materials, optimizing processing technology, strengthening maintenance and cleaning, and improving operating skills are all key to solving the problem of tool wear. In actual operation, we need to choose the appropriate method according to the specific situation, and constantly summarize and improve to improve work efficiency and quality.

As a flange facing machine factory from China, we are well aware of the significant impact of tool wear on production efficiency and processing quality. Therefore, we are committed to the research and development of efficient and durable tool materials. We focus on the fine processing and quality control of products to ensure that every flange facing machine can meet international standards. At the same time, we also provide customized solutions, designed and produced according to the specific requirements of customers. Our products are widely used in petroleum, chemical, electric power and other industries, and are deeply trusted and praised by customers. We will continue to innovate and improve to meet the needs of the market and provide customers with better products and services.

https://www.nodha.com/

NODHA Industrial Technology Wuxi Co., LTD -

AuthorPosts

- You must be logged in to reply to this topic.